Top 10 Features: Analysis tools and Quality Check

Let’s continue the analysis of the main features of ThinkDesign. This month our focus is on the Analysis tools and Quality Check.

ThinkDesign offers a wide range of information and analysis tools, which can be grouped as follows:

- precise geometric measurement tools

- display tools for appearance and shape quality check

- comparison tools and analysis of the differences.

The topic is wide; therefore, it will be dealt in three articles that will be published next, under the same heading.

Design choices or specific requests of changes about a product generally depend on a pre-assessment of the quality of the geometry that is being created. Other important factors are the ability to measure and analyze the geometrical and functional aspects, the 3D model appearance and features, starting from the first phases of CAD modeling. Using virtual models, the capacity to prevent mistakes or defects coming from the geometrical shape becomes strategical. This approach saves a lot of time in the later phases of the product industrialization and manufacturing. In many cases, the possibility to prevent mistakes allows you to take timely choices about shape or size that have an impact in terms of functionalities and quality, or simplify the manufacturing process, with a consequent considerable saving of time and costs. Think at the possibility of evaluating the area of the surface that is to be painted, the possibility of calculating the weight and the center of gravity of an assembly, or the moments of inertia of a sectioned area, the possibility of measuring the size and the area occupied with a detail.

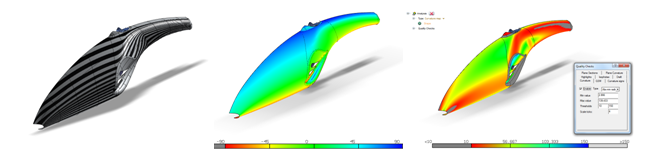

In a complex shape the only 3D visualization may, sometimes, not be sufficient for the assessment of its appearance characteristics. This is why expressly developed assessment tools represent a further opportunity for the designer, who can quickly analyze and predict the appearance and shape characteristics of the 3D model created. Anticipating them on a virtual model reduces, for example, the impact on the prototypes and the changes to be made, or reduces the number of necessary FEA simulations. Consider the possibility to view the lines of light (or zebra lines) of a surface in order to analyze the shape, or to evaluate the silhouette curve and possible undercut areas of a detail that must be printed.

These tools do not substitute the designer’s judgment and choices in the process of CAD modeling, but support the human assessment phase. In fact, only the designer’s experience in the later phases and in the product industrialization process allows the validation – in compliance with the company’s standards – of a result in terms of actual quality of the product.

Geometrically precise measuring tools

These basic control tools are used to check the result of a particular modeling and derive from this analysis a number of very useful indications for evaluating the dimensional and quality aspects of a 3D geometry (typically solids, surfaces, curves or meshes).

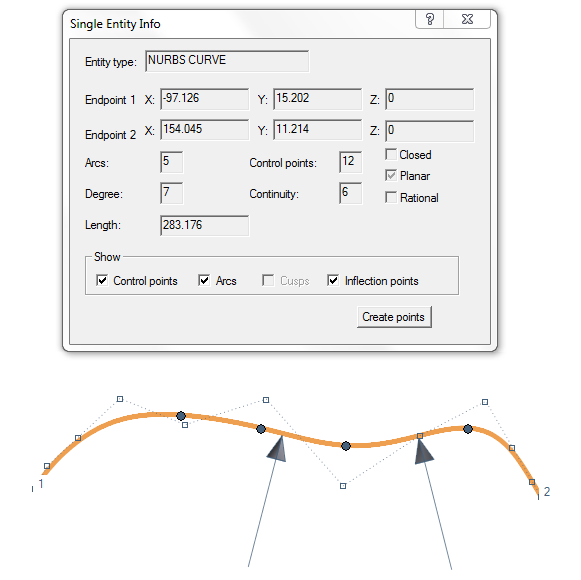

The first command of this group is ‘Single Entity’ that allows users to obtain specific indications such as absolute coordinates of a point, length of curves or boundaries, characteristics of a curve or simply type of selected geometry (planes, cylinders, or NURBS). In the case of curves, for example, it can be very useful to understand if the curve is planar and its complexity (control points, inflection points, curvature).

In the analysis of complex shapes it is often essential to control the characteristics of the curves that generate shapes: original curves of good quality are essential to obtain good quality surfaces.

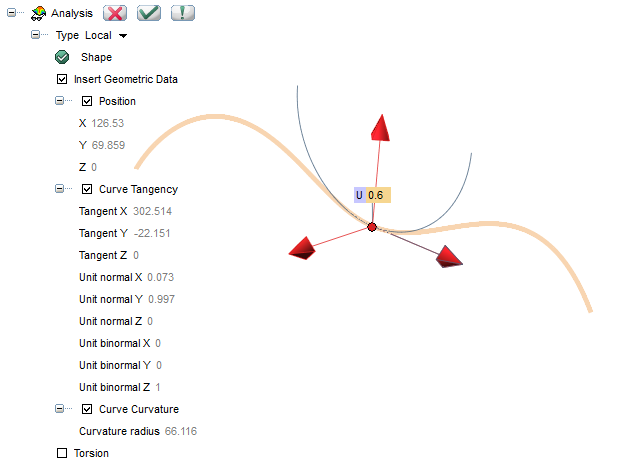

Another tool for a precise analysis is the Local Analysis command (Analysis-Local), which applies on the selection of a curve and that provides a set of indications relating to the tangent vectors at a given point, its sign and the value of the radius of curvature at that point.

The activation of the Insert Geometric Data option allows you to draw directly the normal, tangent and bi-normal XYZ vectors, at the point of the analyzed curve.

Further checks on the shapes can be activated with specific commands such as those that allow you to obtain the area of a set of surfaces, the volume and the weight of a solid or of an assembly.

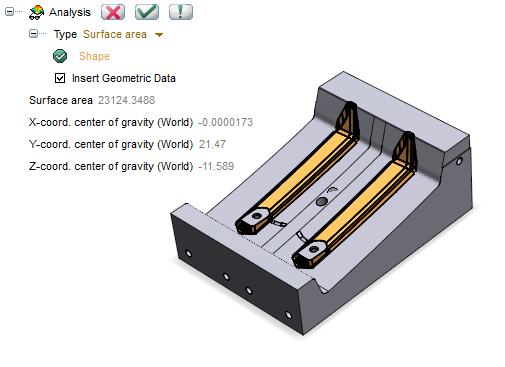

For example, by activating the Surface Area Analysis (Analysis-Surface Area) together with the option ‘Faces’ you can get the calculation of the selected area, useful for example to estimate the amount of paint needed or the costs of a particular surface finish to be applied.

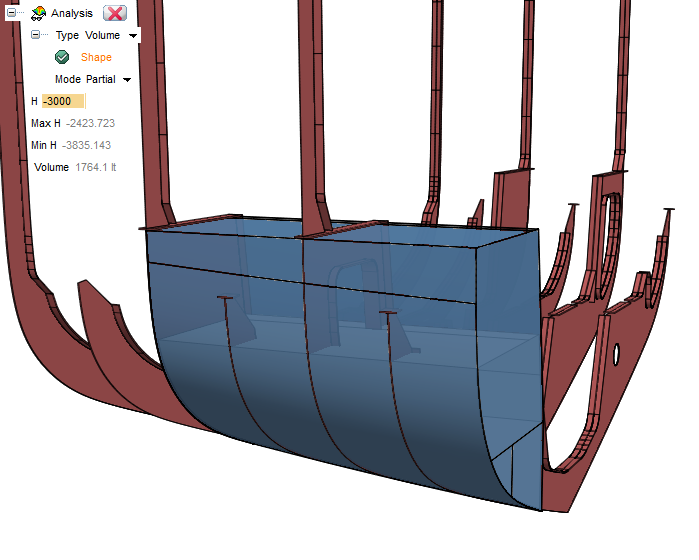

With the Volume Analysis (Analysis-Volume) command you can instead calculate the partial volume of a tank at a specific height.

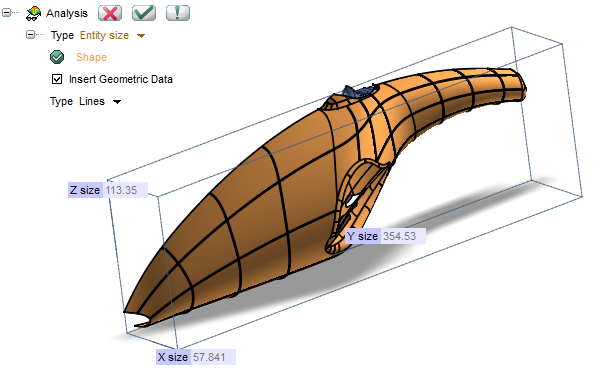

The bounding-box (Entity Size) of an entity may be very useful for measuring its maximum volume with respect to the reference system.

These are just some of the analysis commands available; for more details, see the online documentation of ThinkDesign.

Soon, we will deepen the analysis commands of a 3D model through the different views of quality checks. We anticipate the topic with an image:

See you at next episode!