Focus On: Concurrent Engineering

This month the in-depth analysis is carried out by the PLM Marketing Manager. Through a series of informative articles relating to the issues of Product Lifecycle Management, he deals with the topic of “how to reduce the time to market of a product by putting more activities in parallel” or, in other words, “how to reduce the time to market through the concurrent engineering”.

At the beginning of my professional career, I participated at a seminar on the optimization of business processes, and a data struck me in a special way. I could sum it up as follows:

- a breakthrough of 50% on the development costs of a product, has an impact on its profitability of 3%;

- a breakthrough of 6 months on the development time of a product, has an impact on its profitability of 32%.

At that time I thought that this impressive data was true only for large U.S. corporations for which it had been conceived (the data source was Hewlett Packard), but over time I realized that it can be applied , and probably even in a conservative way, also to the Italian manufacturing SMEs. For them, in fact, only in the best of cases the delay in the release of a product has an impact only on profitability. Very often a delay also involves the risk of losing the client or the contract, paying fines and even losing market shares.

That said how is it possible to reduce the time between the conception of a product and its time to market? Or, in the case of special products manufactured under order, how is it possible to reduce the time between the first contact with a customer and the delivery of the product?

By instinct we tend to think that the “time to market” can be reduced by simply increasing productivity and efficiency, perhaps with the introduction in the company of sophisticated automatic machines, or by acquiring innovative information technology systems, or by increasing human resources, etc.

These solutions are certainly feasible, but very expensive. There is however the possibility of adopting a “technique” that can significantly reduce the time to market, without any major investment, only through the reorganization of some business process, even by optimizing and improving safety through a PLM product.

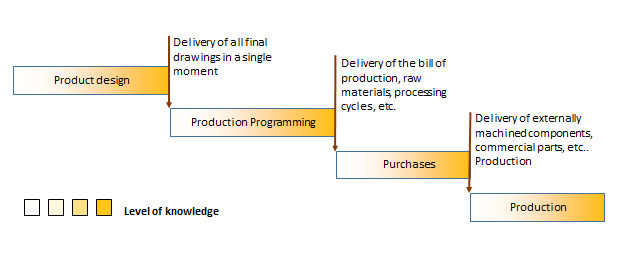

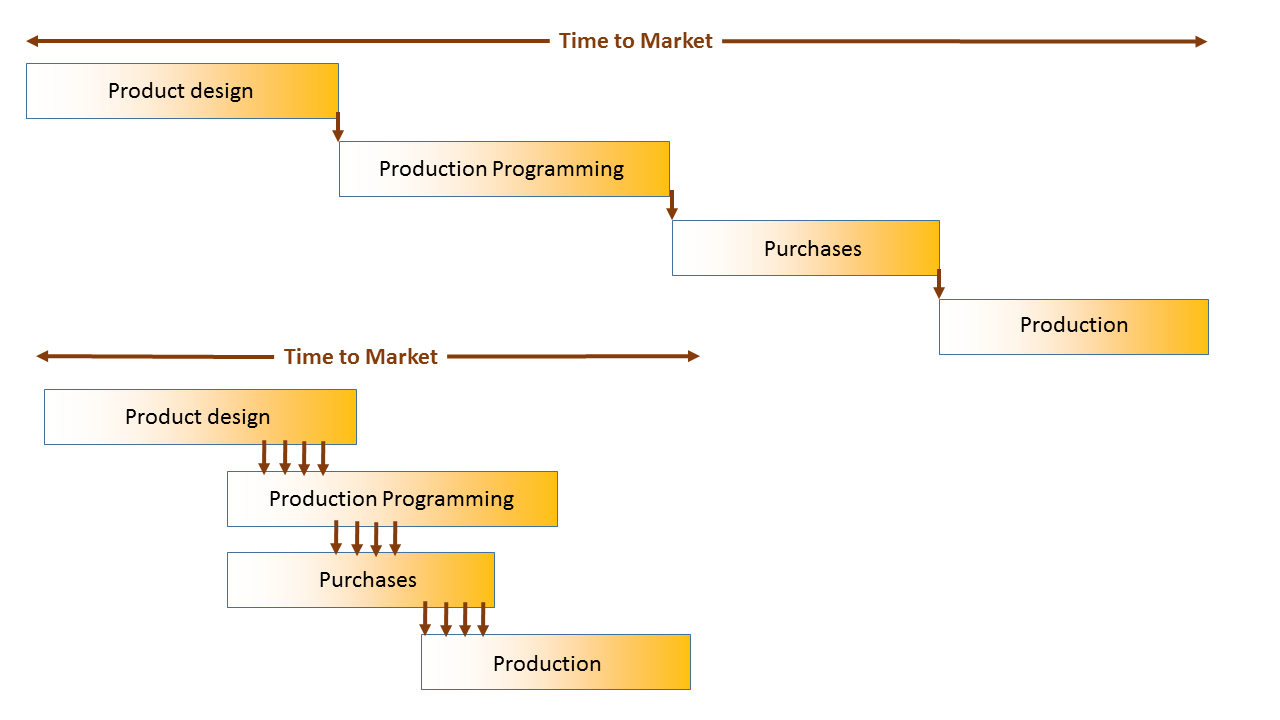

The Anglo-Saxons call this technique “concurrent engineering”, which could be explained in simple words with “doing more things at the same time”. I try to illustrate this technique with the following scheme:

The example reported above is a typical sequential process: each activity starts when the previous one has completed; the level of knowledge of project information starts from scratch at each sequence (since each activity involves different people). Like all schematizations, it represents a quite limit approach, however, a not so uncommon situation, at least for the part of the processes relating to development and production.

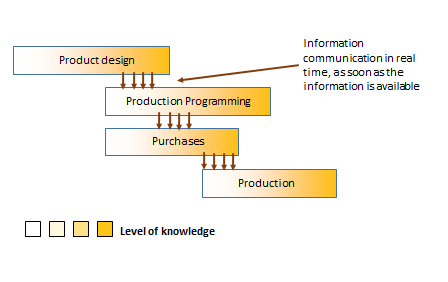

The supporter of the “concurrent engineering” work to convert the previous scheme in the following:

Putting the two schemes side by side, the advantages introduced by the concurrent engineering appear evident, no other comments are needed.

But if the diagnosis is so simple, why is it so difficult to find a solution? Essentially because, actually, often the information is not available when it is necessary; above all, in the practice, it is difficult to be sure to operate on reliable information, when the information is still being processed by third parties.

Here’s where a good PLM system can be properly implemented introducing the concept of “concurrent engineering”. The following results can be obtained using a good PLM system:

- the information is available in real time to all the people involved in the various processes;

- through electronic signature systems and workflow, the information is spread only when it is validated and ascertained;

- the flow of information is favored by a knowledge database accessible in a simple and safe way;

- the paradigm “I’m waiting for some information” is changed to “I can access all but only the information I’m interested in”.

But what is a “good” PLM system? In DPT/think3 we have very clear ideas about this point and in a next newsletter we will be happy to share them with you.