Focus On: Part List

In this issue the Product Marketing presents a study on the information classification and the Parts List creation.

A key element in the final design of an assembly is the product data management: it is all the information, called metadata in jargon, that, connected with the digital model, allows the management and the recognition of the designed details.

The metadata are re-used in all the subsequent stages of design, starting from the purchase of the raw materials for the production, to the after-sales activities. The detail encoding, the creation of the Engineering Bill of Material or the encoding of the final drawings are activities that the designer must face every day. The PLM systems, interfaced with authoring programs for the production of the technical documentation, are the ideal tools for formalizing, managing and sharing information.

But when does this information become available and, above all, which is the best time to insert it in a system?

Inside a company, more users need to access the product information, which are often subjected to changes and integrations. Many variables are involved, such as the size of the company and its organization, but one point is certain: it is the designer who, when creating a detail, has “the keys in hand” to decide what to plan, start classifying the information, and make it available as soon as possible.

The design becomes, therefore, the ideal time to start assigning the information to the designed details … but which systems can be used?

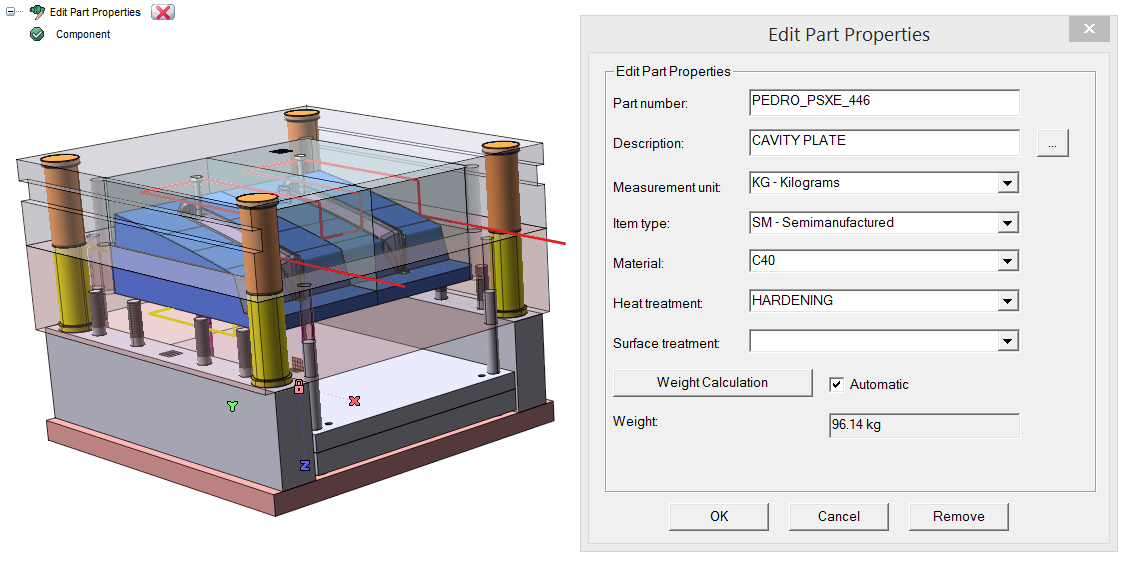

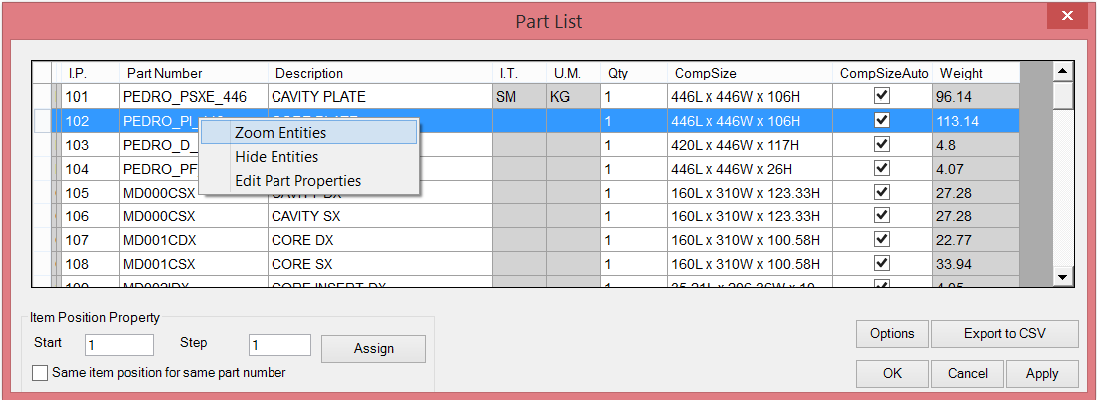

A 3D assembly is organized through a hierarchical structure of details, defined in ThinkDesign as components. The user can take advantage of a default metadata configuration, and assign to each component a quantity of already available standard information, for example code, description, unit of measure, thermal treatment, just to mention the typical information relating to a mechanical detail. Through the “Edit Part Properties” feature, it is possible to classify the information of each component of the assembly, one at a time.

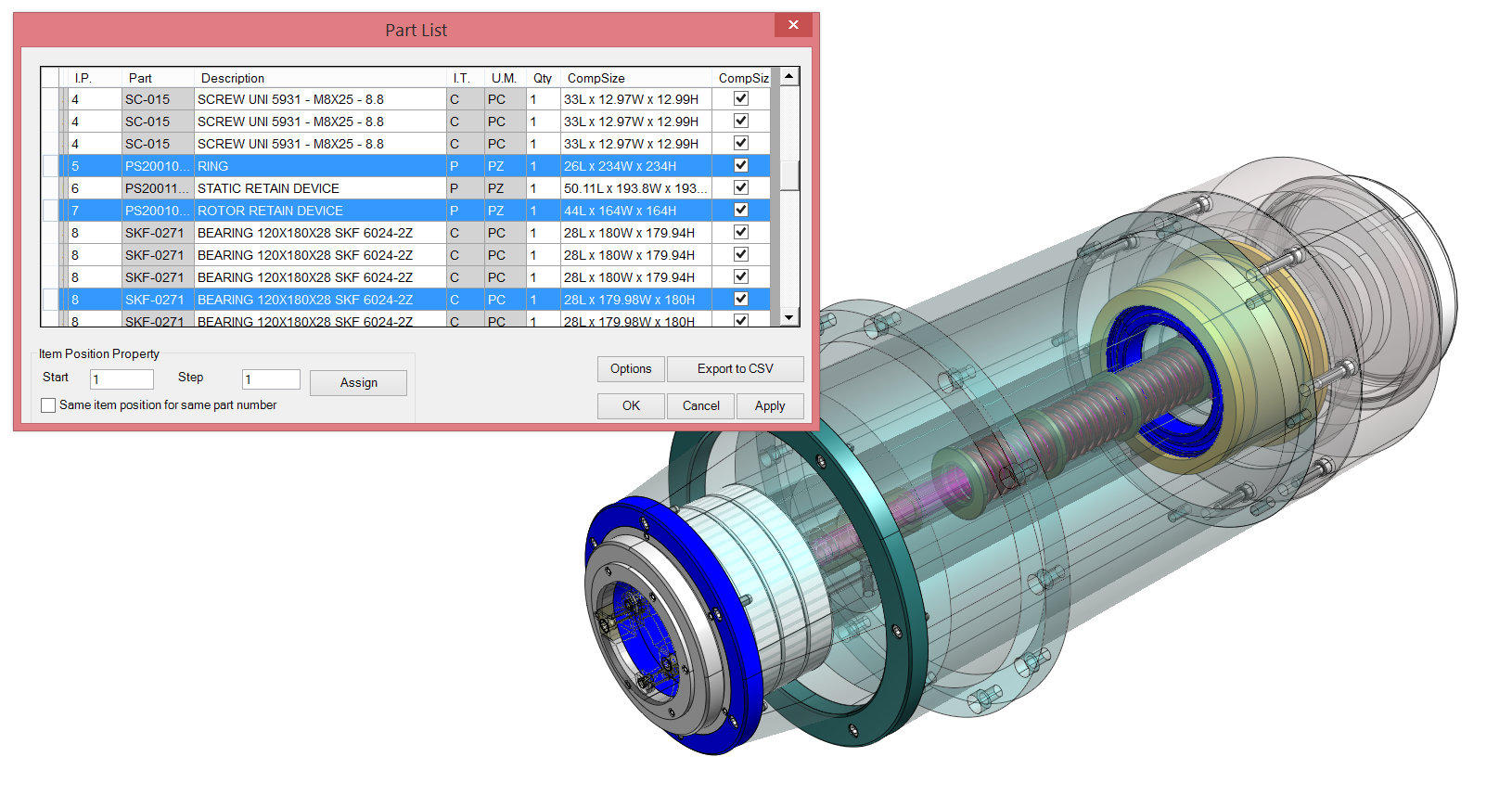

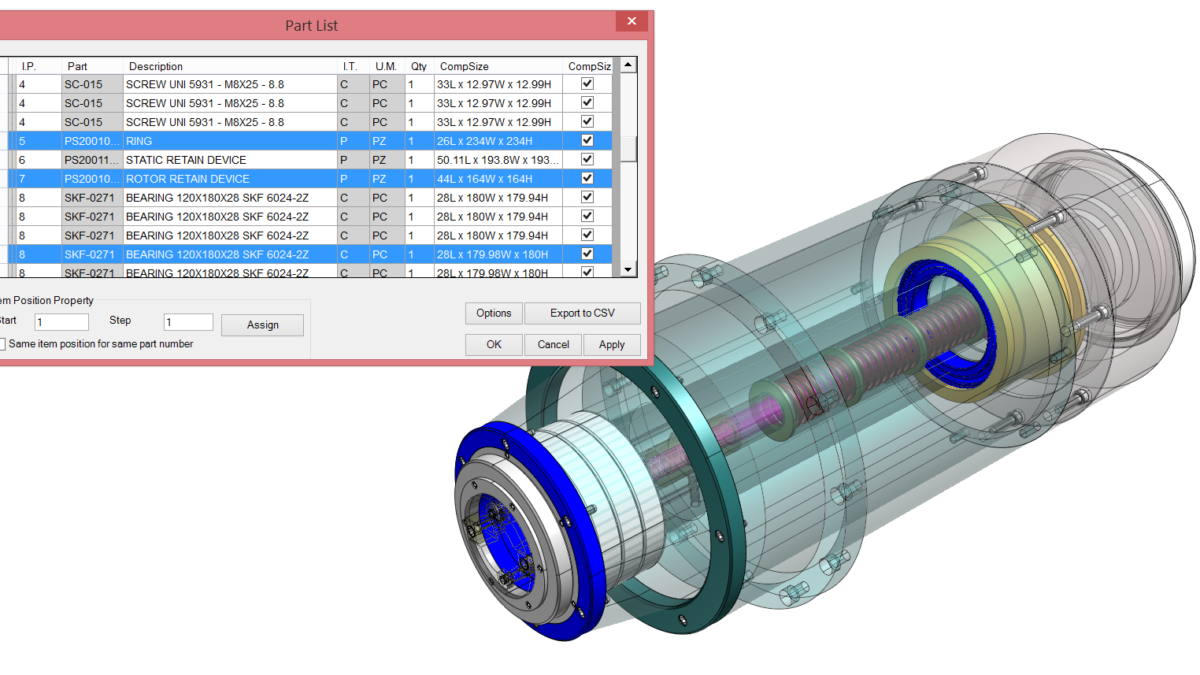

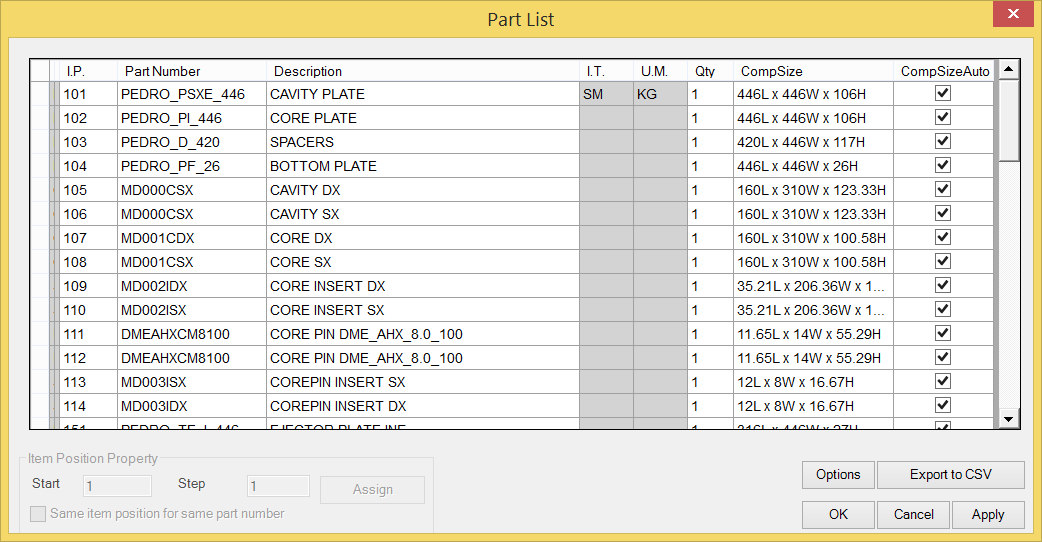

With the latest versions of ThinkDesign, the user can assign the information to the components directly inside the 3D assembly, also through the Part List. The Part List in fact allows browsing the metadata in a table, while having a full view of all the assembly components, thus simplifying and speeding up the information assignment phase. Each row in the table represents a single component.

In this way, regardless of the level of progress in the creation of the assembly, the designer can start taking notes and assigning information to the components, following a process that is very similar to the compilation of the Part List in a spreadsheet.

The ease of use of the Part List table also facilitates the insertion of the data by the designer, who does not have necessarily to delegate this task to the final stage, which usually requires different tools, and can save time and reduce errors.

The 3D model makes available some information, such as weight, cut length or dimensions of the detail box, and therefore provides useful information to appropriately fill the bill of the raw materials that need to be purchased.

Thanks to the Part List, the designer can list the single components with a sequential numbering, alphabetically or by selection, and classify them automatically. Moreover, through a multi-selection the designer can highlight the various components inside the 3D model, making any component search and display easier.

The part list provides some features to export the metadata, collected for each component of the assembly, directly to an ASCII file in CSV format. The exported data can then be processed by using MS Excel (or similar programs) to configure and produce reports, in order to obtain material lists and detail lists.

The process of assigning product information through the Part List is not intended to replace the use of a PLM system. Only the latter, in fact, can provide the infrastructure to validate the inserted data without duplications or using autocode and control automatisms. However, the use of the Part List is a valuable tool to accelerate the product data entry, or anticipate this phase since the early stages of design or during the assembly analysis. It allows in fact the reuse of the information in the later stages, thus improving the communication between the designer and the detail specialist until the final work stage.