SHOEI Co., Ltd.

The Company

Founded in 1959, SHOEI Co., Ltd. has been a pioneer in the production of multi-purpose safety helmets in Tokyo. With a rich history spanning over 60 years, they have become synonymous with "premium" in the global motorcycle helmet market.

Every helmet is meticulously crafted in Japan, combining the latest technology with consumer feedback, advanced materials, and extensive experience in helmet building. An integral aspect of this scrupulous process involves rigorous testing with the most discerning critics of all – their professional Racing Team.

The Challenge

As the motorcycle helmet industry evolved, transitioning from 2D to 3D design became imperative for mold making. Designers faced the challenge of shifting from 2D drawings to creating their own 3D data. This shift required a solution that was not only easy to use but also capable of handling complex surfaces, offering flexibility in modeling and high-quality surfaces in engineering.

ThinkDesign as a Solution

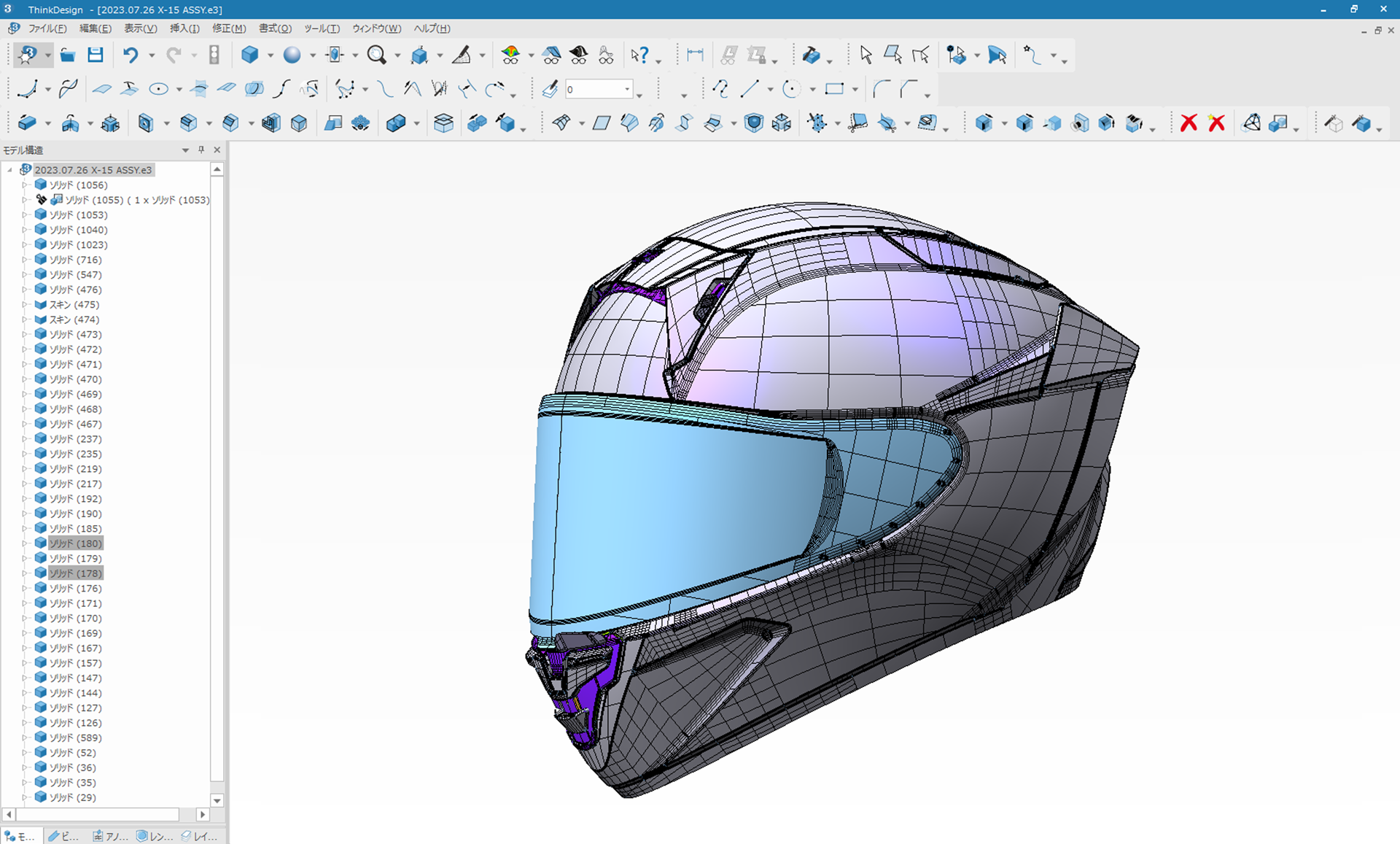

SHOEI fully implemented ThinkDesign into their design process for helmet creation in 2008, and since then, ThinkDesign has played a pivotal role in both the Modeling and Development Departments.

For the Modeling Department, it facilitates the creation of outer shell shapes through a meticulous process that involves importing external data and employing ThinkDesign for modeling and introducing design modifications, such as creating the air intake points for effective ventilation.

Meanwhile, in the Development Department, ThinkDesign plays a crucial role in the initial design phase of the shell shape. The process involves creating a 3D digital master model, which is then utilized by a 3D printer to generate a physical prototype for subsequent wind-tunnel testing. This comprehensive usage of ThinkDesign in both departments highlights its multifaceted contribution to the overall design and development lifecycle of the helmets.

FLEXIBLE MODELING APPROACHES

According to SHOEI, ThinkDesign is very intuitive to use and its users can benefit from multiple modeling methods tailored to their preferences and project requirements. Should one method pose challenges, ThinkDesign seamlessly allows you to explore alternative approaches until the desired shape is achieved. This flexibility ensures a smooth and efficient design process.

Furthermore, ThinkDesign distinguishes itself by offering a hybrid functionality, seamlessly integrating both solid and surface modeling. This unique feature empowers designers and engineers to work with greater versatility, combining the advantages of both modeling techniques to optimize their creative and technical outcomes. Whether one is shaping intricate surfaces or crafting robust solids, ThinkDesign's capability as a hybrid CAD software enhances the overall design experience.

Since adopting ThinkDesign, manipulating surfaces has become incredibly easy.

It stands out for its user-friendliness, and our designers appreciate how easily they can handle it themselves.

ThinkDesign has truly transformed our design process for the better.

FREE-FORM MODELING

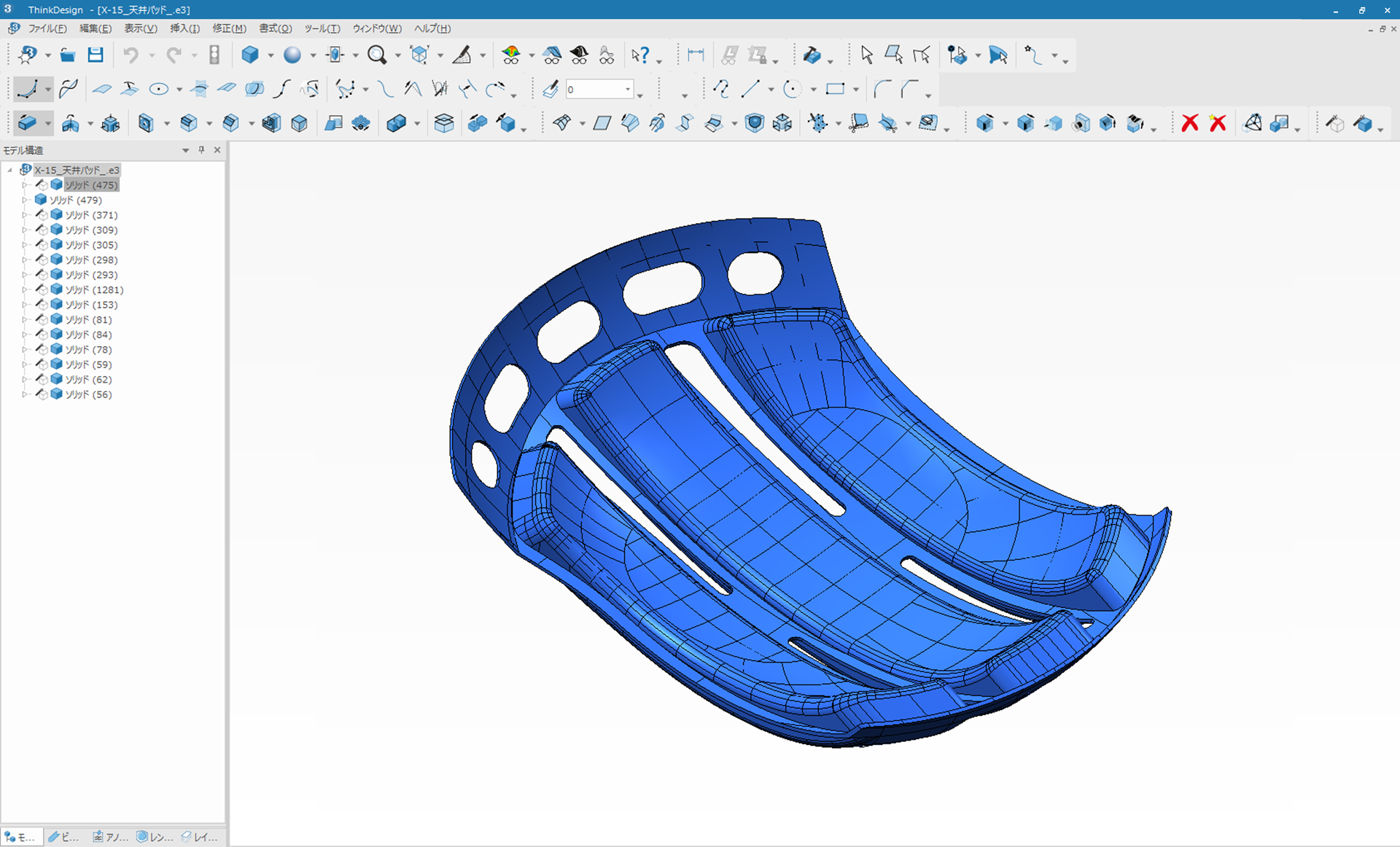

In the Modeling Department, the company has achieved remarkable results using ThinkDesign for designing helmet components. Many parts to be attached to the helmet are designed to align with shell parts, adopting an offset shape. However, challenges often arise during the molding and painting phases, leading to deformations in the helmet's outline shape.

When SHOEI addresses these deformations occurring in the helmet's outline shape and converts them into offset shapes, the use of ThinkDesign's Advanced Global Shape Modeling (GSM) proves to be beneficial as it allows for deformation under different requirements.

For example, it is valuable in areas where they want to keep the stroke of the shape or the outline.

Moreover, during the creation of the helmet's face, while Surface Modification commands are available for specific deformations, the Modeling Department increasingly relies on the Advanced GSM due to its versatility in meeting various design requirements.

It has significantly contributed to the success of the company's helmet design process.

Another of the key aspects appreciated by SHOEI’s engineers in the Development Department is ThinkDesign's ability to import curves and lines from 2D drawings and create 3D models by applying solid features. They find particularly useful also the several advanced surface and curve commands for high-quality results.

INTERACTIVE SOLID MODELING

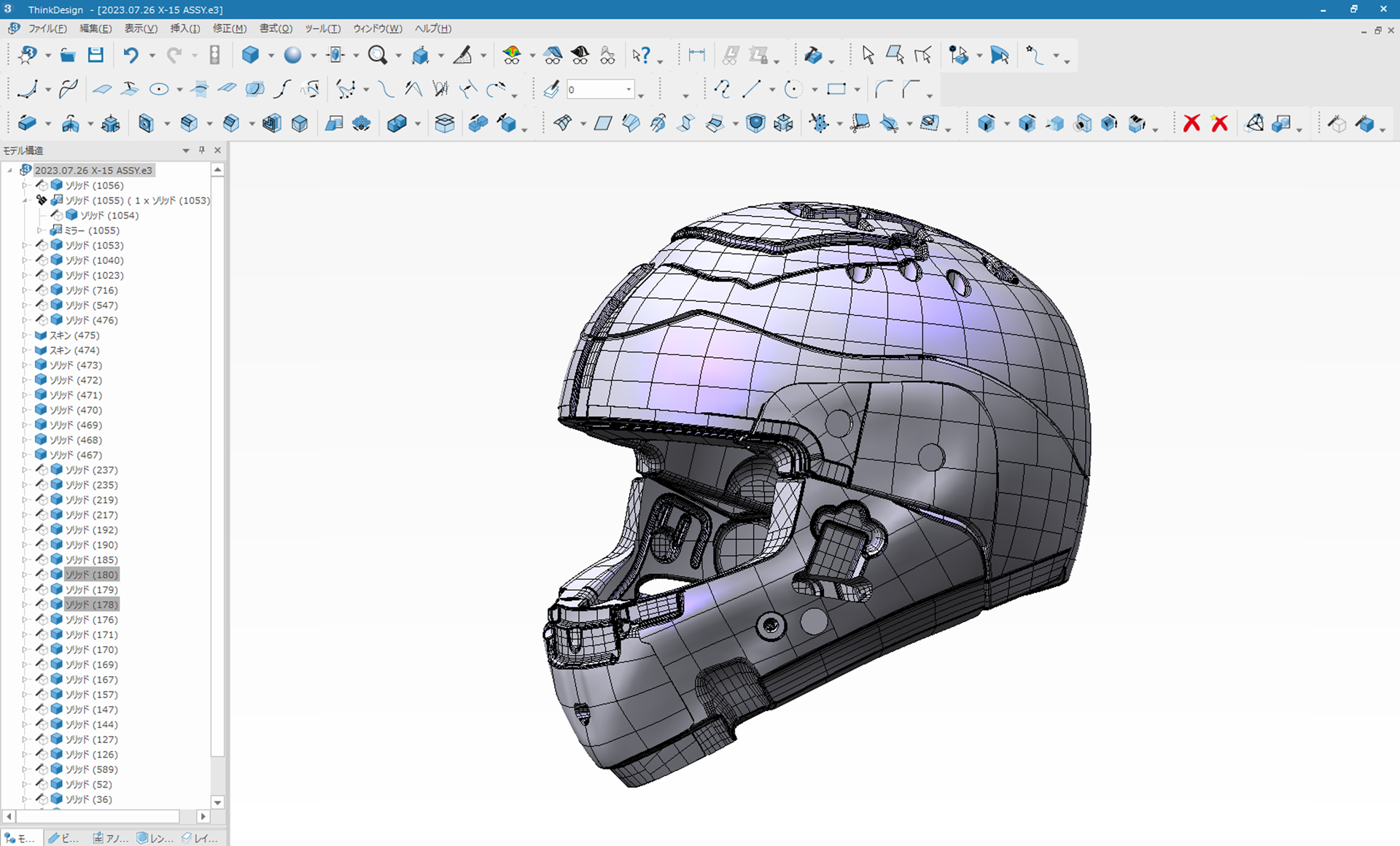

SHOEI has found that the Interactive Solid Modeling (ISM) features in ThinkDesign provide a powerful capability for removing fillets from a solid model. With this Interactive Modeling approach, users can make topological modifications to a solid without requiring access to the model's history and parameters.

They can directly select the faces of the solid that need to be modified, eliminating the necessity to redefine the parameters associated with the parametric modeling history. This streamlined process enables efficient and direct adjustments to the solid model, offering a more intuitive and flexible approach to modifying fillets without being constrained by the traditional parameters of the model's history.

Conclusion

The implementation of ThinkDesign revolutionized the design and engineering process of SHOEI, making it more efficient and cost-effective. The software's user-friendly interface allowed designers to handle the transition from 2D to 3D seamlessly.

The benefits included a significant reduction in the time and cost of creating 3D data, previously outsourced to external companies. The ability to review and modify data internally led to a substantial decrease in lead times for helmet production.

ThinkDesign’s impact extended to both the Modeling and Development Departments proved to be particularly useful. The program's flexibility in handling different design requirements, its intuitive nature, and its ability to create beautiful and functional shapes distinguished it in the market.

In summary, the decision of SHOEI to adopt ThinkDesign was motivated by its ease of use, competitive pricing, and its effectiveness in handling surfaces.

The transition from 2D to 3D design became a smooth journey, leading to increased efficiency and innovation in SHOEI’s helmet designs.

Today, ThinkDesign stands as a keystone in the their design process, enabling them to continue creating their premium and meticulously crafted motorcycle helmets.