Toyoda Gosei Co., Ltd.

Toyota Motor Corporation Group

The Company

Founded in 1949, Toyoda Gosei is part of the Toyota Motor Corporation group, and has more than 70 years of experience in delivering top-notch products and services based on synthetic rubber and plastics and associated mixing technology.

Working in the automotive industry, Toyoda Gosei must face the significant transformations presently characterizing the market, such as the advancements in electrification and autonomous driving, but also the deepening environmental and social concerns. Despite these uncertain conditions, the company is succeeding in adapting proactively, embracing these challenges while maintaining a commitment to its polymer-based assets.

This sentiment is also mirrored in the company's guiding philosophy, which states "Pursuing the possibilities of polymers, we will contribute to a future of better mobility and living".

The Challenge

Before the introduction of ThinkDesign, Toyoda Gosei Co., Ltd. was facing insufficient flexibility in shape definition, encountering several challenges that were impeding their progress and hampering their design quality.

Also, the company needed a powerful tool to quickly and accurately embody their client’s design needs, in order to significantly reduce the time required for complex modifications.

It was essential for such tool to be high-performance and able to assist throughout the entire process, from concept design modeling to the creation of Class A surfaces, especially in those cases where the molds are directly engraved with the design data and high speed is required.

ThinkDesign as a Solution

ThinkDesign provided the ideal solution to address these challenges.

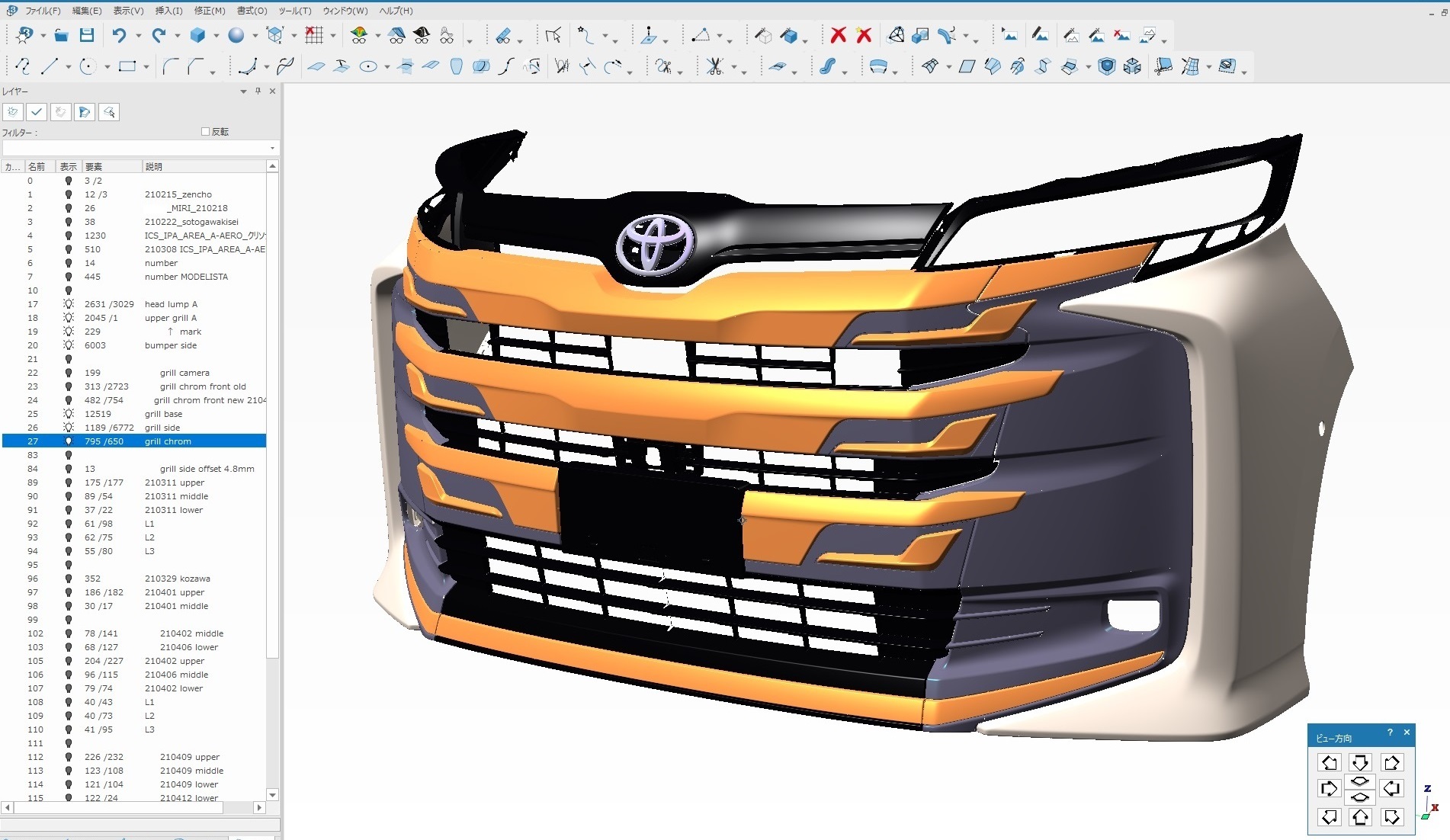

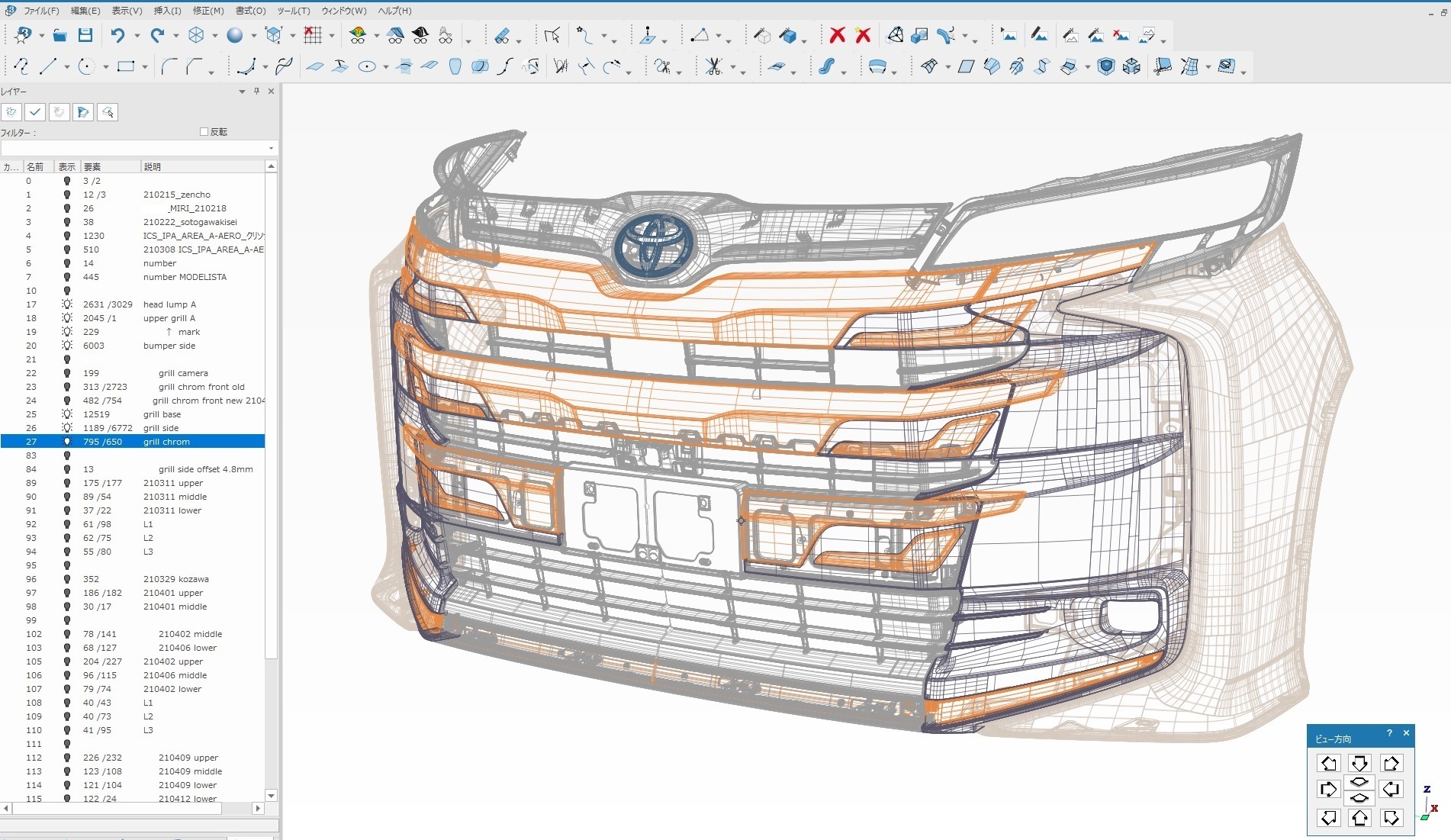

DPT’s CAD software was introduced in the Design Development Department, and it is used to design automotive aftermarket parts such as aero parts, bumpers, radiator grilles, side garnishes.

Since the adoption of ThinkDesign, Toyoda Gosei has consistently followed the product evolution, keeping pace with its latest releases.

The implementation of ThinkDesign has yielded remarkable results for the company.

FREE-FORM MODELING

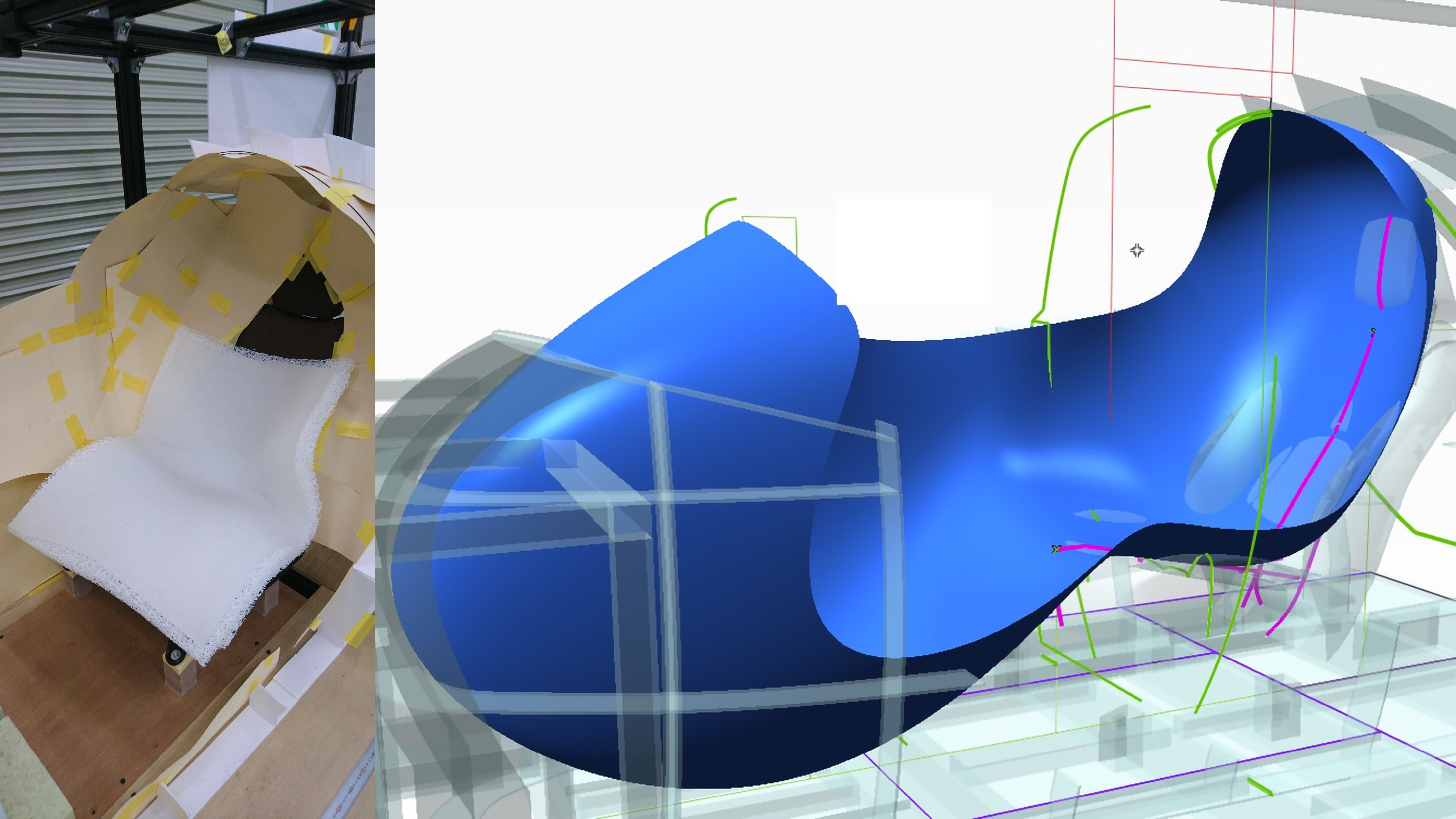

The advanced Global Shape Modeling (GSM) features of the program offered the flexibility and precision needed for complex designs, allowing to modify the shape of entire objects - composed of solids, surfaces, curves, points and meshes - in minutes, rather than hours or days.

Through the use of the Advanced GSM command, the company has achieved several significant advantages in their design and development processes, such as efficiently creating complex surfaces, which were previously quite challenging.

This capability has not only improved the quality of their designs but has also made their products more appealing to customers.

Our expertise and know-how has grown significantly with ThinkDesign. Advanced GSM's impressive capabilities have been pivotal in helping us overcome numerous challenging phases. Even when confronted with unforeseen changes in conditions from the carmaker, we are able to minimize the workload and the stress caused by such changes without being burdened by them.

MAXIMUM FLEXIBILITY

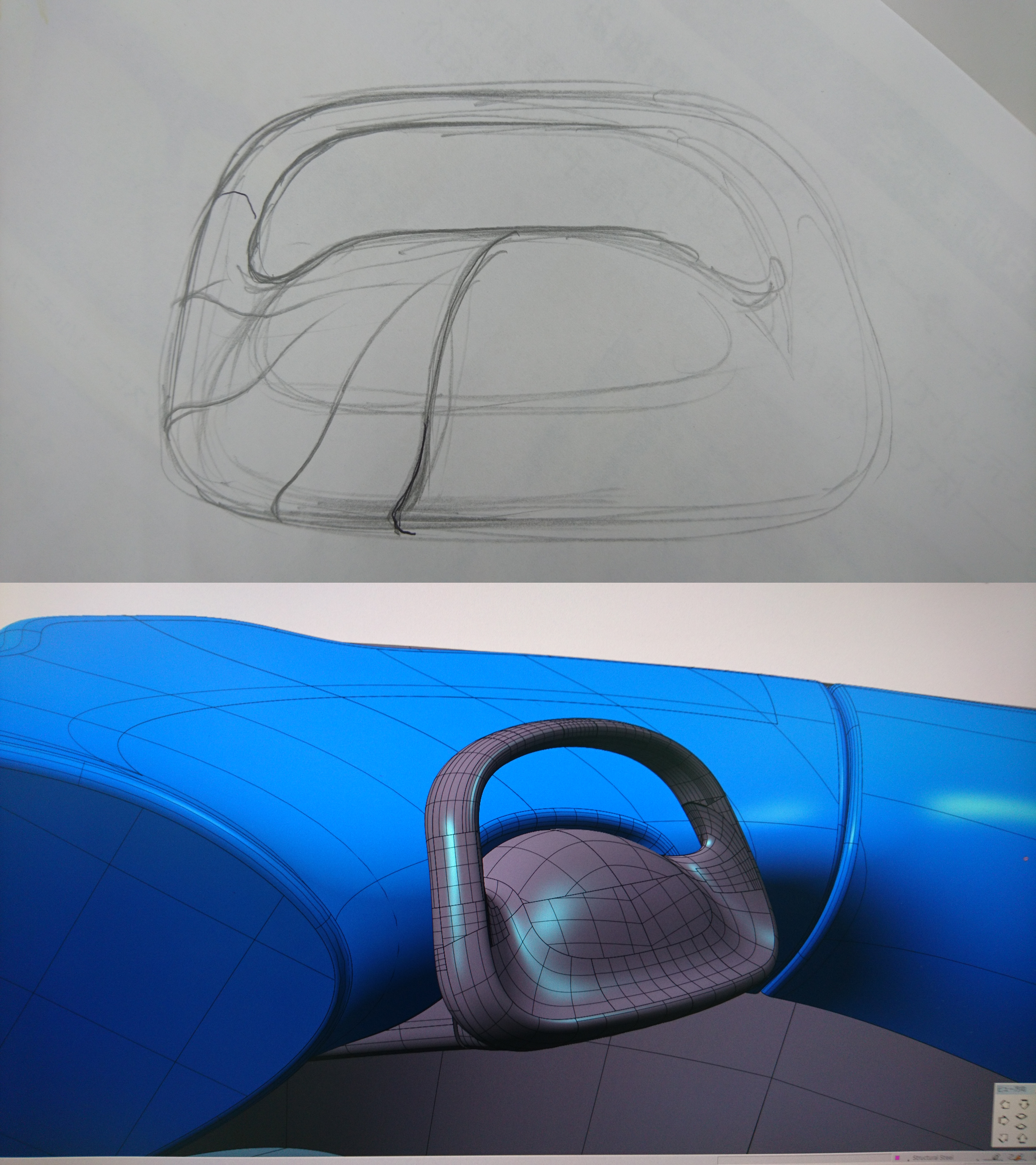

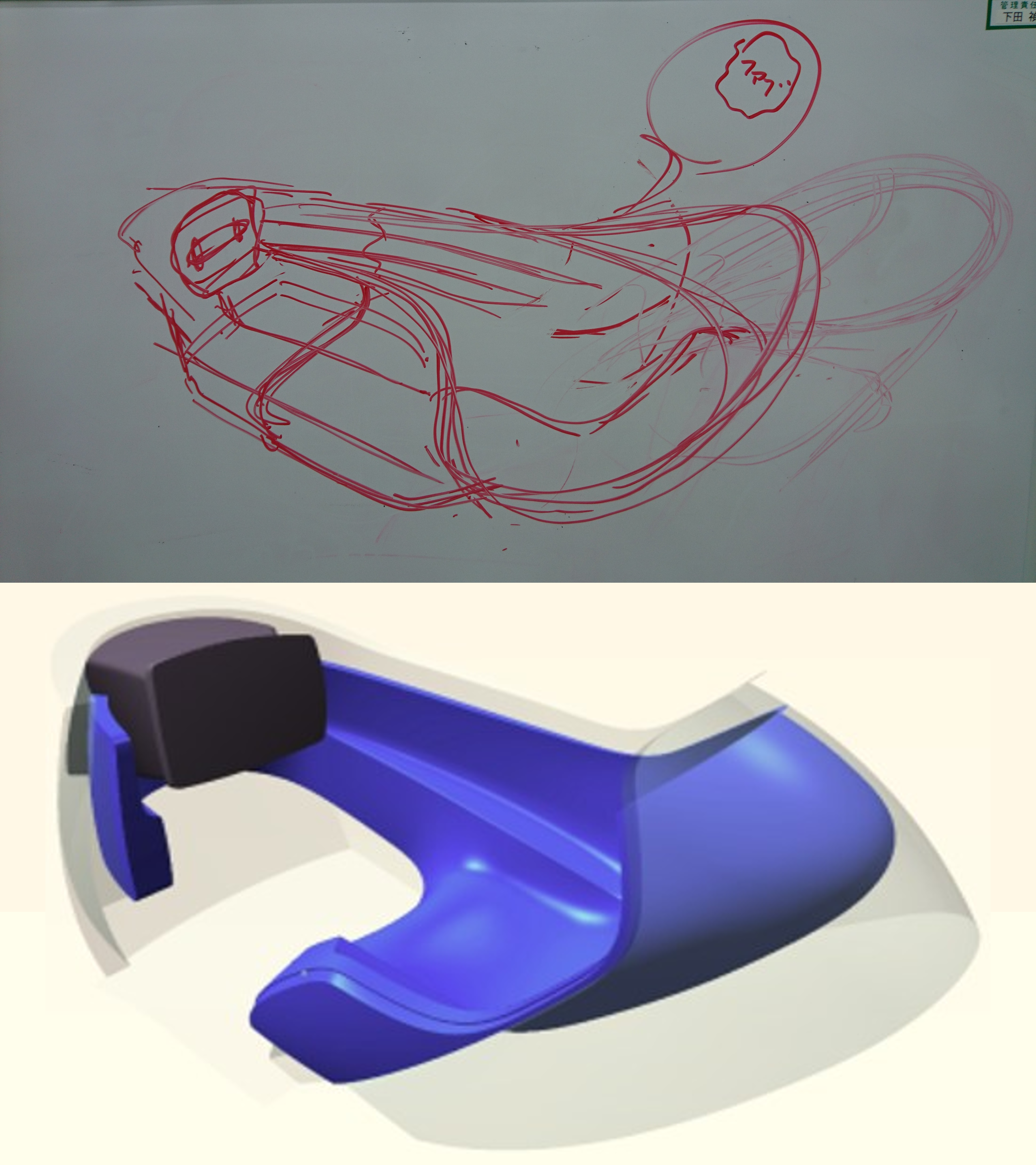

Furthermore, ThinkDesign has facilitated rapid design iterations, allowing Toyoda Gosei to swiftly generate 3D shapes from initial sketches. This agility has proven invaluable in meeting the fast-paced requirements of the automotive industry and accommodating quick design changes effectively. Reflecting design requirements and costs in the conceptual phase is in fact necessary to secure orders from automotive manufacturers.

This unique ability to offer support right from the initial conceptual phase of sketch design allows Toyoda Gosei to stand out in the market.

By anticipating and addressing potential design challenges and optimizing manufacturability, it contributes to the overall innovation and efficiency of the product development process.

In addition, the Advanced GSM command has given the flexibility to create intricate and customizable designs.

HIGH-QUALITY REVERSE ENGINEERING

ThinkDesign's capability to re-create Class A surfaces starting from data scanned from clay models allows the company also to simplify and speed up the design iterations.

In addition, they have the possibility to create proportional surfaces thanks to the Lofted Surfaces command, which proved to be fundamental to ensure great flexibility and to maintain the integrity of the shape throughout the development process.

HIGH-PRECISION CONTROL TOOLS

Being interested in displaying curvature in real-time, Toyoda Gosei has been able to reach this goal thanks to the ThinkDesign’s Curvature command. This useful tool allows for immediate adjustments and superior quality control as you can check the quality of your curves while creating or modifying them.

With the implementation of ThinkDesign, we've been able to increase the frequency of design review meetings

with our clients from once a week to two or three times a week.

This accelerated pace has often surprised some automotive aftermarket manufacturers and carmakers.

REDUCING TIME TO MARKET

Most significantly, ThinkDesign has led to a substantial reduction in design time-to-market. This has enabled the company to perform numerous comprehensive design reviews for their clients, thereby increasing customer satisfaction with their design services and elevating their reputation above that of their competitors' design departments.

Conclusion

The implementation of ThinkDesign has significantly impacted the company's design and development processes, resulting in improved product quality and ROI, accelerated time-to-market, and substantial design cost savings.

Global Shape Modeling (GSM) has played a pivotal role in the company's success by enabling precise and rapid design changes, reducing the time needed for complex modifications.

ThinkDesign has revolutionized the company's approach to automotive parts design, empowering them to enhance design quality and reduce development costs.

This partnership between Toyoda Gosei and DPT is an awe-inspiring testament to the power of creating significant design modeling know-how through the use of ThinkDesign and outperforming the competitors’ design department in the automotive aftermarket.