Top 10 Features: Global Shape Modeling & Advanced Modeling

Let’s continue with our in-depth analysis on Global Shape Modeling, by exploring the many features of the Advanced Modeling command.

In the previous articles, we illustrated how to make free-form changes with the commands Bend, Planar Bounding-Box (GSM Planar Bounding-Box), and 3D Bounding-Box (GSM 3D Bounding-Box). All these commands allow the designer to work interactively moving points and deforming the object to reach the desired result.

With the Advanced Modeling approach, instead, to make changes, you need to define precise matching rules between points or curves. The Preserving and Matching conditions allow you to define a rule of spatial point transformation to be applied to the object to be modified.

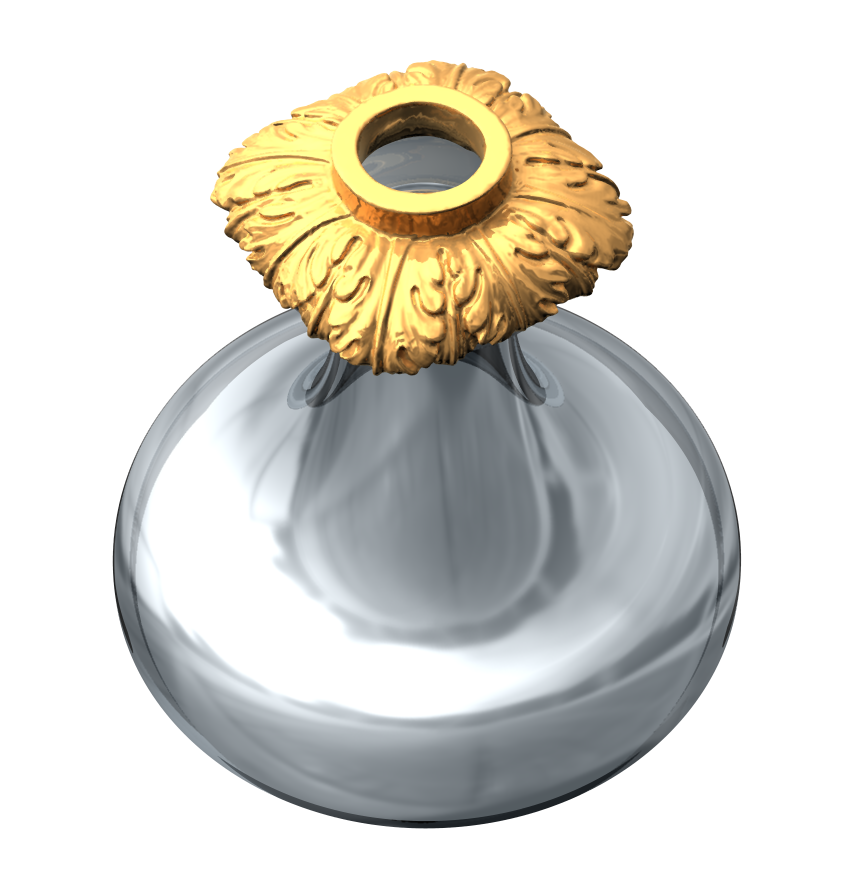

Let’s consider the model of the Lorenzo’s Cup (Coppa Lorenzo), a design object created by Baldi, the historic Florentine company that uses ThinkDesign in the process of development and design of its products. Baldi, a leader in the sector of luxury furnishing, represents, with prestige, the high quality of the ‘Made in Italy’ in the world. Each product is created as if it were a jewel to adorn and embellish the house.

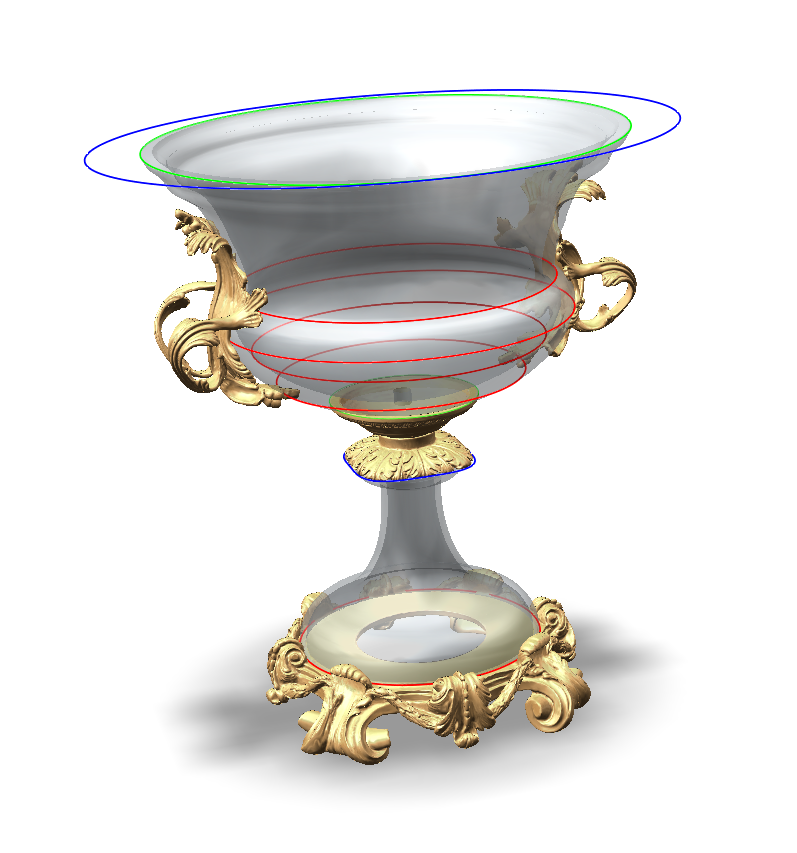

Baldi’s models combine artistic and organic forms with geometric shapes, they are typically hand-crafted and scanned through a sophisticated process of Reverse Engineering. The image above illustrates the details of a crystal cup and the artistic decorations of the handles and the base.

With the traditional modeling, you can easily create details with geometric shapes, and the parametric/associative approach allows you to perform quickly and timely size changes, also variations to the initial model.

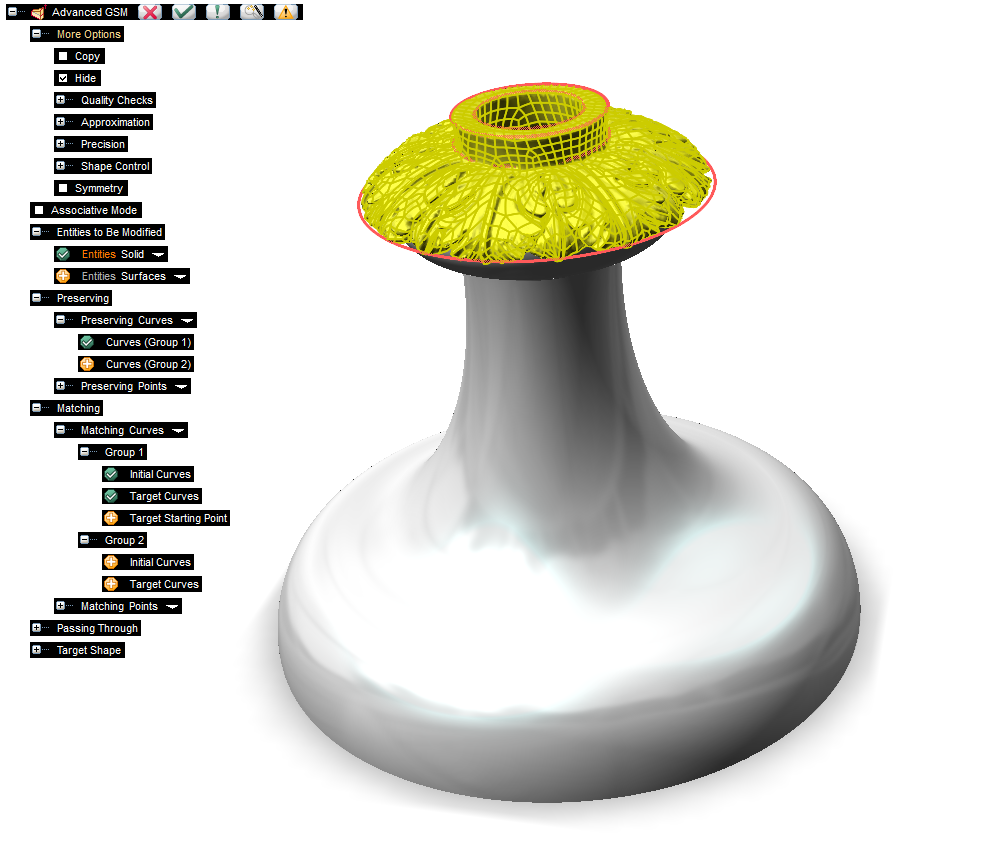

However, how can we manage the details obtained with Reverse Engineering? The results of this process are usually static and rather complex shapes. In these cases, the use of traditional tools implies considerable limitations. Let’s consider the decoration ring. You must adapt it to the diameter of the crystal base while keeping unchanged the section of the neck, then insert the neck into the shaft and the assembly screw.

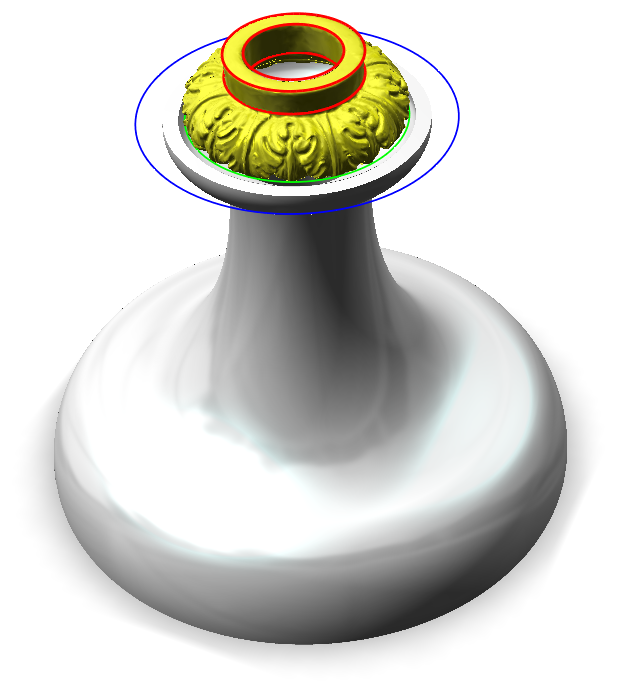

The Advanced Modeling technique allows you to use curves as condition rules. Refer to the image here above: the red curves represent the Preserving condition, the green curve the start condition, and the blue curve the target condition of the Matching mode.

Specific precision parameters allow you to control the level of accuracy and obtain the best results. The operation is performed immediately and you do not need to set any shape matching between the target conditions.

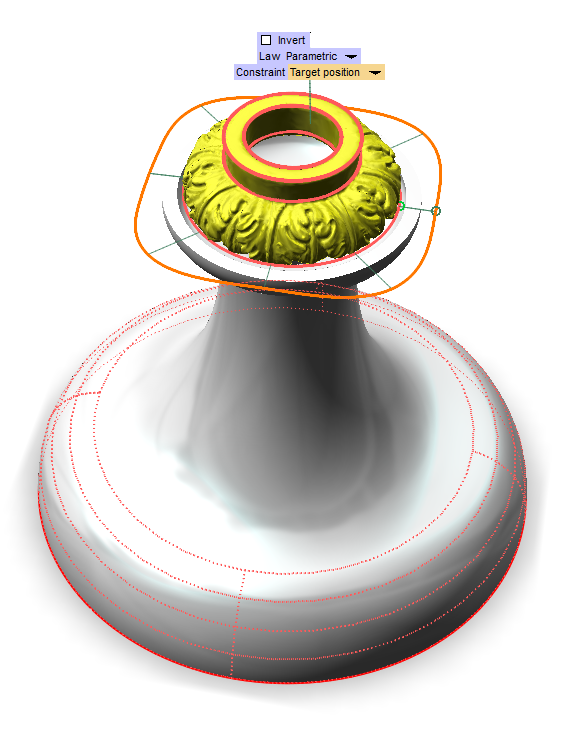

The Advanced Modeling also gives you the opportunity to change the style of the object. For example, you can use the circle as start curve and the new rectangular section as target curve, by maintaining the red curves as Preserving condition. You can also add the red curve of the base and the relating tangency condition as further Preserving conditions.

This approach enables you to modify not only the decoration ring, but also the base surfaces, obtaining an alternative different style of the product.

The Advanced Modeling does not involve any constraint to the definition of the modification rules and therefore can provide many valid alternatives.

Now let’s try to change the top of the cup with an elliptical cross section, by keeping unchanged the circular shape of the lower area of the cup (red curves).

In this case, a change is applied to the cup shape: thanks to the possibility of controlling the shape in the various points, you can apply the modification to the static geometries. For this reason, even in an advanced stage of the project, you can make changes with a great flexibility.

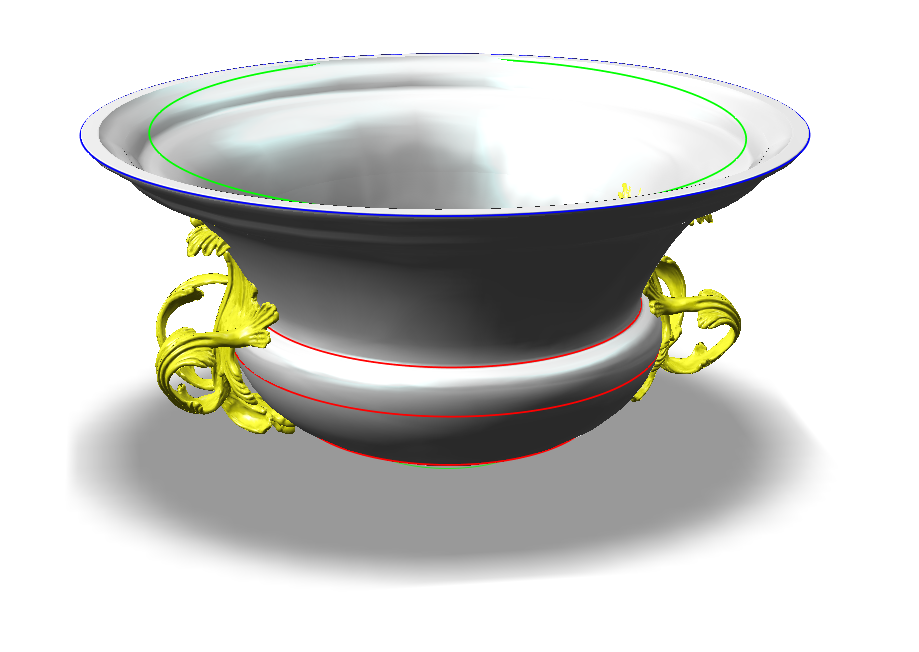

The modification to the shape of the cup requires the adaptation of the support area and, consequently, the revision of the shape of the handles also obtained through Reverse Engineering.

Thanks to the Replicate function (GSM Replicate), you can apply the same mathematical rule previously used for modifying the surfaces. If you select a surface, as start condition of the rule, and the handles, as the solids to be modified, the geometric deformation previously applied to the cup, is extended to the handles, thus obtaining the desired effect.

A few seconds of calculation and a new prototype is ready to be produced!

Note: All images and models in the article are the exclusive property of Baldi srl.