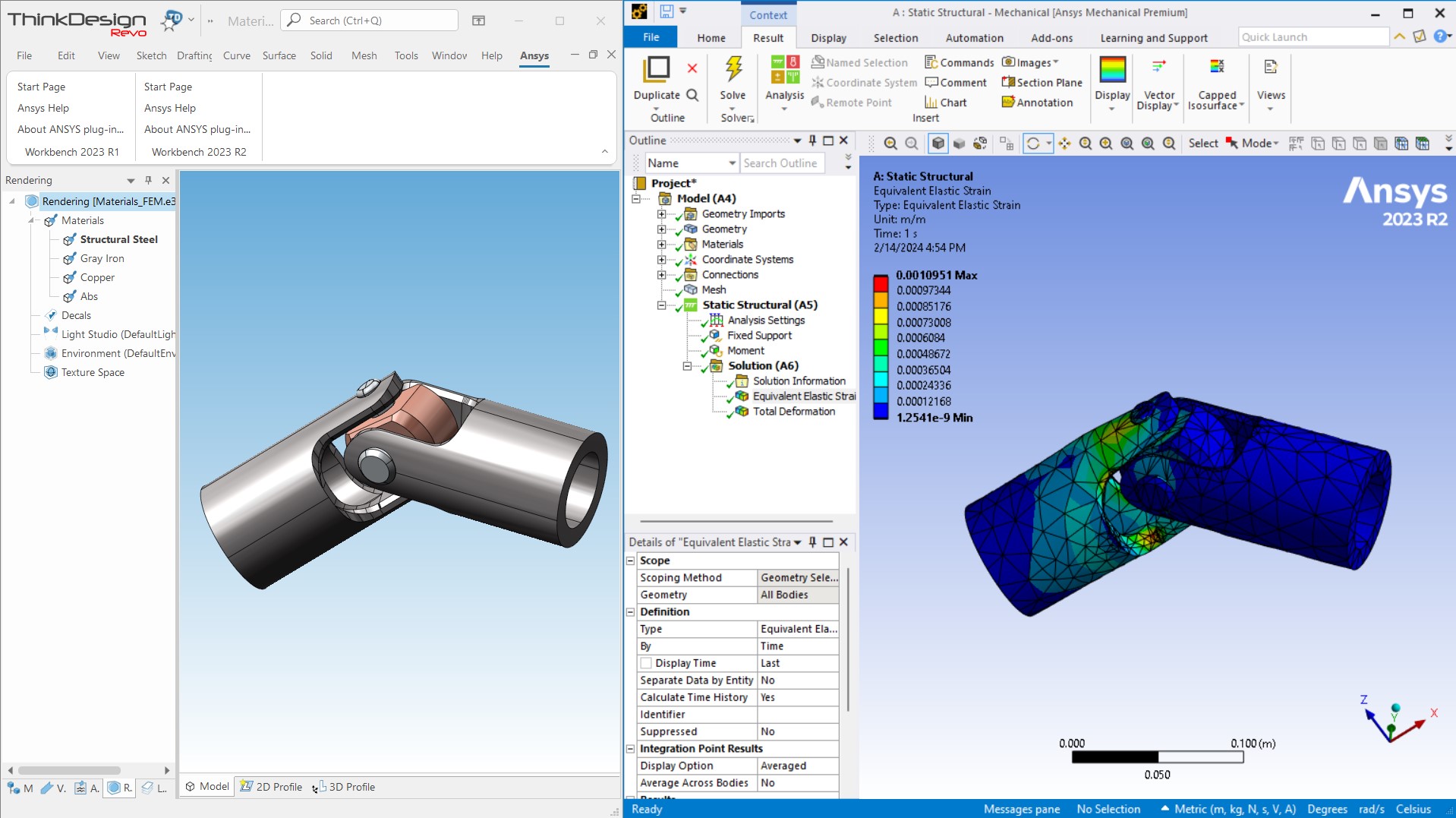

Integrated workflow between ThinkDesign and Ansys

With the 2024 Release, ThinkDesign offers Engineering and Analysis workflow capabilities thanks to the associative integration with Ansys Workbench.

The technologies of 3D CAD design have certainly introduced a number of advantages, such as the new and extended functionality of product simulation, allowing users to analyze and preview the actual operation behavior of a virtual model generated with CAD applications.

The tools for geometric evaluation provided by ThinkDesign include a set of analysis commands, enabling users to quickly obtain information on volume, weight, area, radius of curvature, moments of inertia, and motion simulation. However, when you need to include details about how parts operate in specific environments or simulate material behavior under certain loads, the CAD system alone isn’t enough.

It is necessary to use CAE technology, which employs a “FEM solver” (Finite Element Method solver), enabling the execution of simulations under the desired conditions.

Simulation can be performed in many ways, including structural analysis evaluation, thermal and fluid dynamics analysis, and durability analysis, all considering a product under specific environmental conditions.

Thanks to the recent evolution and simplification of CAE technologies, the number of designers needing to access simulation analysis during product development to anticipate and validate design choices is increasing.

From ThinkDesign to Ansys

The availability of specific design and simulation technologies is, of course, a great advantage. A single application can provide specialized high-level features that allow users to optimize their specialization and freely select the most suitable tools for their purpose. In a typical workflow, the model is exported from the CAD to the CAE program, where the simulation process can be conducted.

Based on the results obtained from the FEM analysis, the process can be iterated to make the necessary corrections or optimizations to the CAD model.

For this purpose, the users of ThinkDesign can now take advantage of the simulation environment provided by the Ansys plug-in, which significantly streamlines the interaction between CAD and CAE, leveraging the benefits of such integration.

Ansys Workbench is an environment specifically tailored for product simulation and stands out as one of the most popular and comprehensive simulation environments available on the market. It provides a wide range of analysis types and offers specific and dedicated User Interface commands to meet various simulation needs.

Starting from version 2024, ThinkDesign is providing an associative integration with Ansys Workbench, and this is available to all ThinkDesign users without the need to buy additional modules. The only prerequisite is that both ThinkDesign and Ansys must be installed on the same PC.

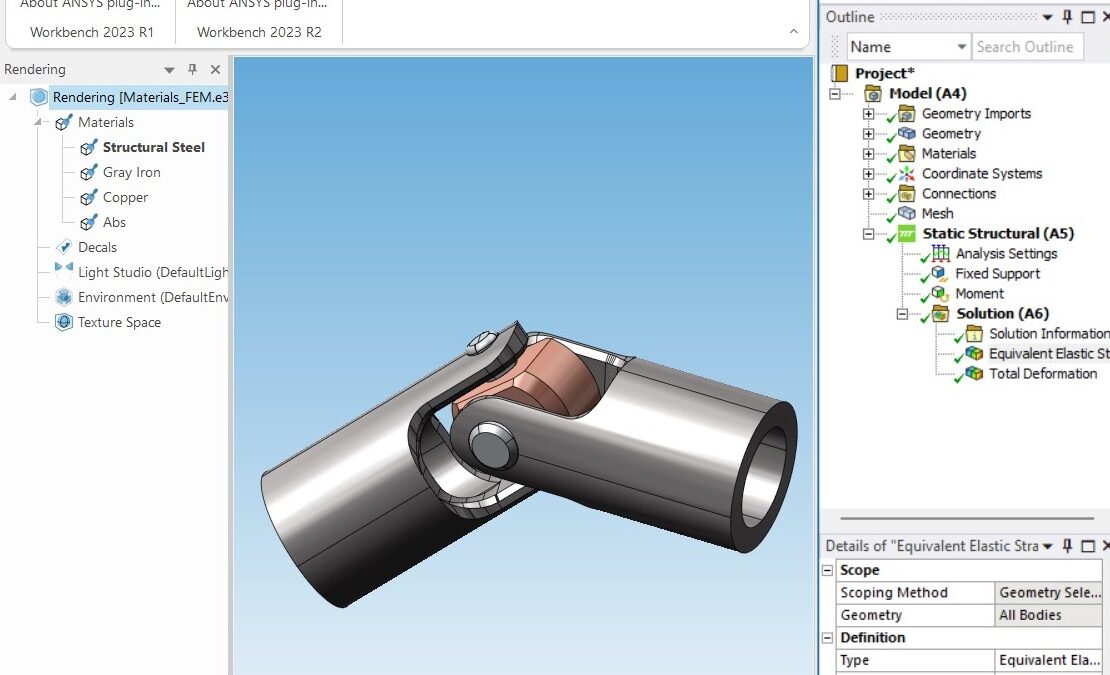

In order to examine the benefits of this integration with a practical example, it is possible to simulate a simple workflow of structural analysis.

After building the model with ThinkDesign, you can start the simulation environment of Ansys Workbench by clicking the “Start Page” button.

Depending on the type of project selected in the “Geometry” section, all models opened in the current session of ThinkDesign are accessible to the user, who can then link the model to the current project. Exporting the file is not necessary because the simulation environment can directly access the geometry of ThinkDesign.

It is possible to import solid geometries, assemblies, surface models/skins and any variables of the parametric model from the CAD model. The interfacing parameters of the integration can be defined in the project properties.

Regarding the project setup phase, upon starting the simulation environment of Ansys Mechanical, the model geometry is automatically loaded and becomes available within the simulation environment.

During the interfacing phase between ThinkDesign and Ansys, in order to easily recognize the assembly details in the simulation environment, various components are identified and inherit the names assigned to them during the model creation in the CAD environment. Moreover, when the model is loaded, a contact of “bonded” type is automatically assigned to all the parts in contact.

Subsequent steps include defining the constraint and load conditions, selecting the type of plotting analysis to perform and, finally, displaying the result.

Setting aside a detailed evaluation of the obtained solution, once the selections are completed, the user can directly intervene on the geometry and modify it through various tools.

Since the model is available in ThinkDesign, the user can directly modify it within the CAD environment without needing to save it in the simulation environment. The “Update Geometry” feature of the simulation environment allows the user to calculate the new solution directly on the CAD model. Once the desired result is achieved, the model can be saved and validated inside ThinkDesign.

Moreover, in the case of a parametric model, any parameter can be controlled in the simulation environment by iterating the calculation until the desired solution is achieved. The changes to the model will be made based on the defined variables.

Compared to what was happening with older versions of the product, the integration has been enhanced, enabling also the correspondence between the “Name of the Material” assigned to the model and the one used in the simulation environment.

ThinkDesign 2024 is now integrated with the latest versions of Ansys, and we are committed to maintain this compatibility going forward.

Simulation studies on virtual prototypes enable a significant reduction in testing costs and can decrease, or even eliminate, the need for physical prototypes. These simulation tools are not only easy to use and seamlessly integrate into the product development process, but they also help designers become more aware of the functional aspects, from the early stages of the design concept.

Do you need more information about the integration with Ansys?